mSafe

Safety Valve Control System

Designed for SSV / ESD Applications

Improve performance with electric-over-hydraulic emergency shutdown control that enables condition-based monitoring and maintenance

The mSafe2 Safety Valve Control System enables you to independently operate two single-acting hydraulic valves from a single panel economically, while maintaining enhanced well safety, increased operational efficiency, reduced maintenance costs and production maximization. Features include:

- Open, close, and monitor hydraulically actuated safety valves - remotely, automatically or at the wellsite.

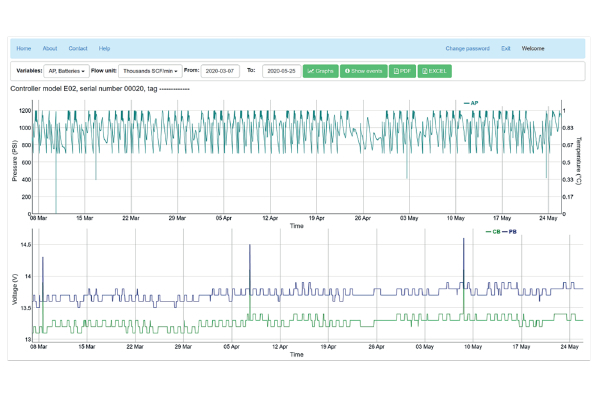

- Condition based monitoring and maintenance are carried out via SCADA or MODBUS RS485 Protocol for complete operational visibility from wherever.

Electronically-Assisted Hydraulic Control

The mSafe2 integrates electronic control and an electro-hydraulic pump to ensure the safety and performance of hydraulically actuated safety valves used in emergency shutdown applications (ESD). The controller precisely and reliably manages valve position while monitoring and maintaining hydraulic pressure in the actuator and actuator lines. The acquired data supports condition-based monitoring and maintenance, which significantly improve safety and performance. Real-time and historical valve data is transferred via SCADA system.

The low power, battery-operated control system is easily charged using wellsite power or solar panels on remote wellsites1.

Specifications

| Base | 35 x 32" (88 x 80 cm) |

| Height | 67" (170 cm) |

| Weight | 207 lbs. (94 Kg) |

| Hydraulic Connection | 1 x 3/8" Tube |

| Electrical Connection | 1 x 1-1/2" NPT Female |

| Hydraulic Outlet Pressure | 300 to 3,000 PSI (1 to 207 Bar) |

| Oil Volume | 1 Gallon (3.8 L) |

| Operating Temperature | -40°F to 185°F (-40°C to 85°C) |

| Electric Power Required | 14 to 72 VDC |

| Control Current | 17W (1.42A @12VDC) (Low power SIL2): 1.5W (0.125A @12VDC) |

| Communications | Modbus RS 485, TCP/IP, HART and USB port¹ |

| Accuracy of measurement | .+ - 1% |

| Response Time | 1 second (ESD) |

| Memory Capacity | >6 months |

Notes:

Solar ready as standard; Low Power SIL 2 is an optional upgrade and recommended for solar applications.

Benefits

Reduce Wellsite Visits

Partial Stroke Test

Monitoring & SCADA Control

Conditioned-Based Monitoring

The mSafe controller’s ability to acquire and communicate precise data on even small changes in hydraulic pressure supports condition-based monitoring and maintenance in many ways: Predictive maintenance is enabled by early detection of small operational anomalies. Partial stroke testing allows diagnosis of potential valve failure without stopping production and with zero emissions. Maintenance is reduced and easier to schedule and production delays are minimized.

Management by exception and the identification of best practices benefit from mSafe data acquisition and identification of deviations. Pressure stabilization eliminates progressive valve closure and associated wear with mSafe monitoring and automatically compensating for temperature-induced variations. Line break detection identifies gradual losses in absolute pressure over time. Deviation from the pressure gradient prompts a mSafe programmable alarm or valve closure.